1. Magnet-ka neodymium-ka waxaa inta badan laga sameeyaa daawaha budada ah ee neodymium, iron, iyo boron kaas oo la isku daray kulayl sare iyo cadaadis si loo sameeyo alaabta la dhammeeyey.

2. Isku darka budada ah waxaa lagu ridayaa caaryar ama weel waxaana lagu kululeeyaa heerkul sare si ay u bilowdo inay dhalaaliso oo ay fiddo.

3. Marka maaddadu gaadho barta dhalaalkeeda, waxa lagu hayaa heer kulkan in muddo ah ilaa ay ka sii adkaato hal gabal oo aan lahayn dalool ama dildilaac u dhexeeya qaybaha.

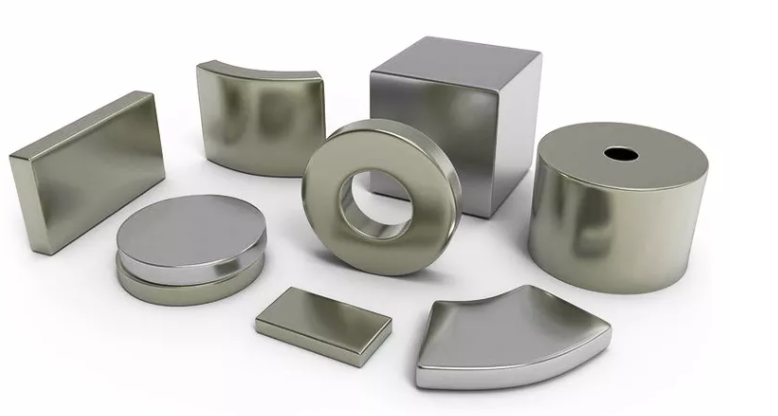

4. Ka dib markii adkeysigu dhacay, magnetka waxaa lagu farsamayn karaa qaabka iyo cabbirka la rabo iyadoo la isticmaalayo qalabyo kala duwan oo wax lagu gooyo sida mishiinka wax lagu shubo ama lathes iyadoo ku xiran shuruudaha codsiga.

5. Cidhifyada birlabeedka ayaa markaa si siman loo simi karaa haddii la rabo ka hor inta aan lagu dahaadhayn dahaadh ilaalin ah sida nikkel ama zinc ujeedooyin iska caabin daxalka ah.

Faahfaahin dheeraad ah ka baaraandegidda, fadlan si naxariis leh u eeg jaantuska socodka hoose:

| Maya | Socodka Geedi socodka | Tallaabada Wax-soo-saarka | Hawlgalka farsamada |

| 1 | Kormeerka Qalabka Ceyriinka | 1.ICP-2.Falanqaynta kiimikaad-3.Analyser(C&S) | Rohs Detection Imtixaanka curinta Falanqaynta Daahirnimada |

| 2 | Qalabka Ceyriinka ka hor daawaynta | 4.Sawing- 5. Qalajinta- 6.Nadiifinta Saamaynta | Bir-madaxeed Qalajinta hawada kulul Nadiifinta Saamaynta |

| 3 | Xakamaynta walxaha | 7.Kontoroolka walxaha | Miisaanka Batching Isku qas walxaha ceeriin |

| 4 | Qaadista Strip | 8.Vacuumizing-9.Melting-10.Kaxaynta | faaruqinta dhalaalay dhalaalid Qaadista |

| 5 | Hoosudhaca Hydrogen | 11.Pre-treating-12.Vacuumizing-13.Add Hydrogen | ka hor daawayn faaruqinta Waxaa burburiya Hydrogen |

| 6 | Milling | 14.Shattering-15.Shiidida-16.Jet Mill-17.Xakamaynta Granularity | Burbursan shiidid Jet Mill Cabbirka Joogtada ah |

| 7 | Cadaadiska | 18. Miisaanka budada -19.Pre-pressing - 20.Cudurka -21.Cadaadiska isostatic | Miisaanka budada Horay u cadaadin Cadaadiska Cadaadiska isostatic |

| 8 | Sintering | 22.Vacuumizing- 23.Sintering -24 Daawaynta kulaylka | faaruqinta Sintering Daaweynta kulaylka |

| 9 | Kormeer | 25.BH qalooca-26.PCT-27.Tijaabada cufnaanta -28.Roughcast Inspection | Cabbirka magnetic Tijaabada isku xidhka heerkulka PCT Cabbirka Cufnaanta Kormeer |

| 10 | Makiinada | 29.Griding -30.Wareer goyn-31. Goynta daab gudeed | shiidid Goynta silig Goynta daab gudaha ah |

| 11 | Tijaabada muunada QC | 32.QC tijaabada muunad | Tijaabada muunada QC |

| 12 | Xubin | 33.Hambalyo | Xubin |

| 13 | Korantada | 34.Electroplating Zn 35. Electroplating NICUNI 36.Phosphating 37. Kiimikada Ni | Electrolating Zn Korantada NICUNI Fosfatinta ama Kiimikada Ni |

| 14 | Kormeerka Dahaarka | 38. Dhumuc-39. Iska caabin daxalka -40.Dheef-41.-Baaritaanka dulqaadka | Dhumucda Iska caabinta daxalka Ku dhegganaanshaha Kormeerka Dulqaadka |

| 15 | Magnetization | 42.Baaritaanka Dhamaystiran- 43.Calaamadeynta- 44.Habaynta/Kacdoonka- 45.Magnetization | Kormeer Dhamaystiran Calaamadayn Habayn/Kacdoon Magnetization Imtixaanka Fiux Magnetic |

| 16 | Baakad | 46. Flux Magnetic- 47.Bagging- 48. Baakad | Boorsooyinka Baakad |

Waqtiga boostada: Febraayo-15-2023